XSHPCB Rigid-Flex PCB Service

- More Efficient Advanced Technology & Perfect Solution

- uperior Reliability and System Cost Savings

- Free Rigid-Flex PCB Quotation and Ordering System

Rigid-Flex PCB is formed by pressing and combining the flexible and rigid board according to the relevant process requirements.

Mainly Applications: Cell Phones, Digital Cameras.

More Efficient Advanced Technology & Perfect Solution.

SPECIFICATION

RIGID-FLEX BOARDS CAPABILITY

Layer Counts

1-32 layers

Build Time

3days - 2weeks

Board Size

Min : 6mm x 6mm Max : 457mm x 610mm

Board Thickness

0.6mm - 5.0mm

Copper Weight (Finished)

0.5oz - 2.0oz

Min Tracing/Spacing

3mil / 3mil

Solder Mask Color & Silkscreen Color

Same as Normal PCBs

Surface Finish

HASL - Hot air solder leveling Lead - free HASL - RoHS ENIG - RoHS

Min Drilling Hole Diameter

8mil

Impedance control

±10%

Other Techniques

HDI Gold fingers Stiffener (only for PI/FR4 substrate)

STACK-UPS STRUCTURES AND DESIGN

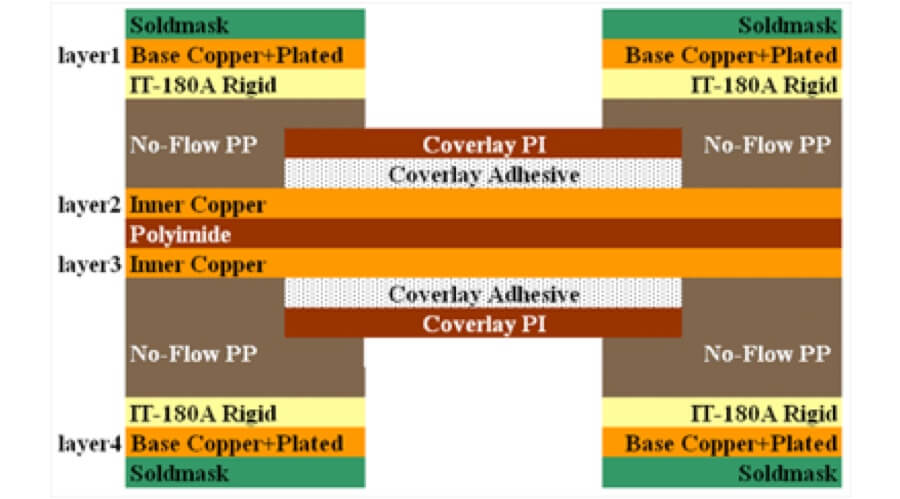

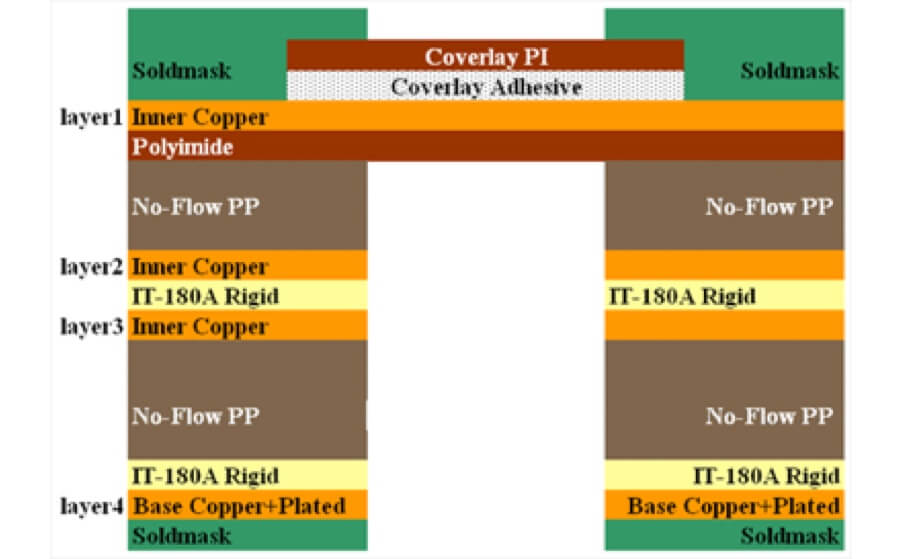

Non-lamination rigid-flex board

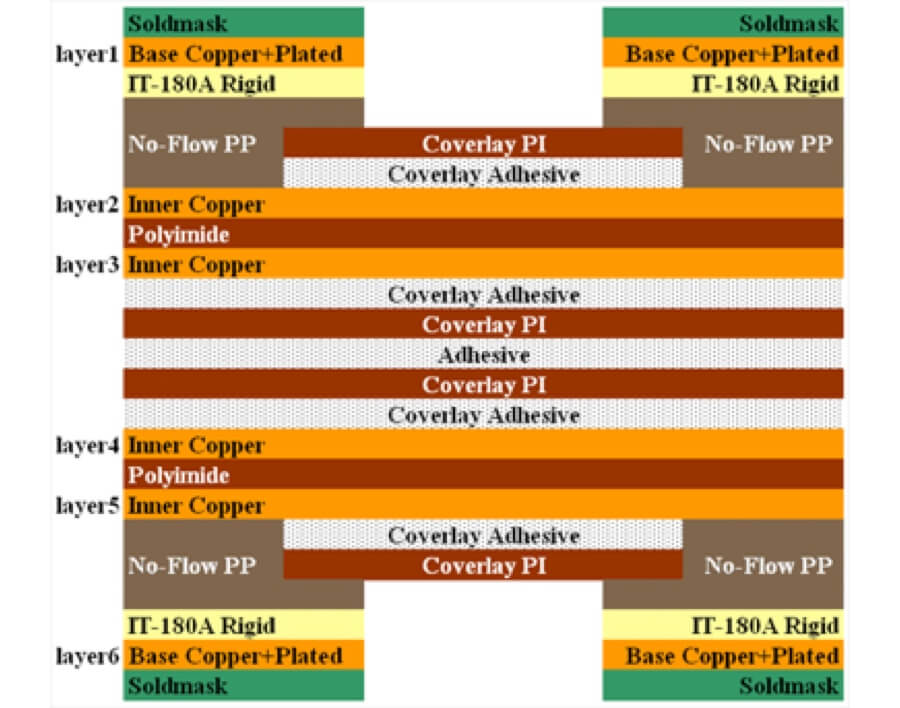

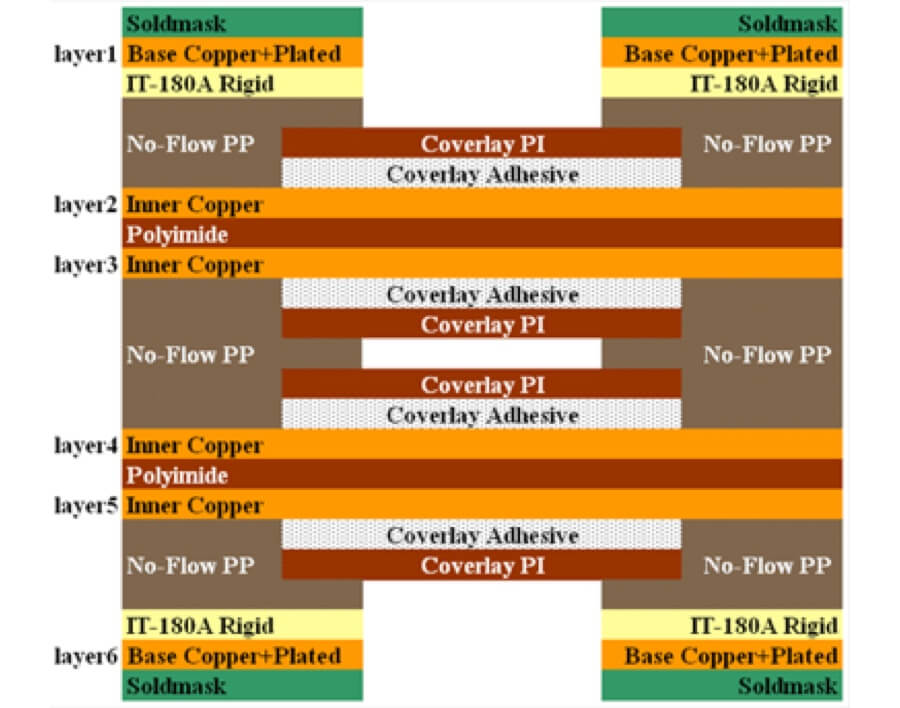

Lamination rigid-flex board

Non-lamination rigid-flex board

Lamination rigid-flex board